How VSD technology helps to

Reduce Energy Used by Compressed Air Systems

Fixed-Speed vs Variable-Speed Compressors

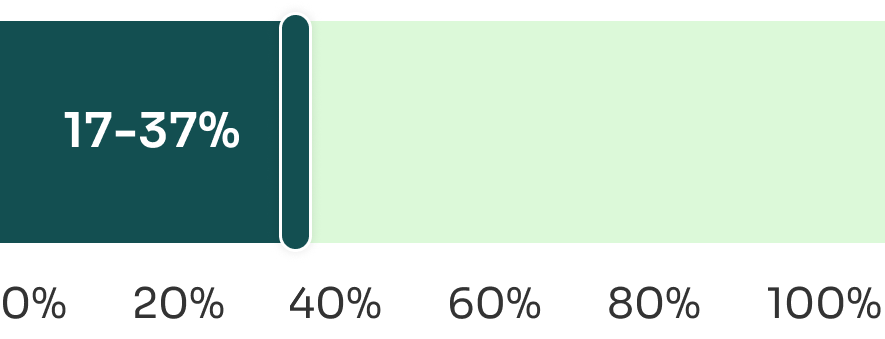

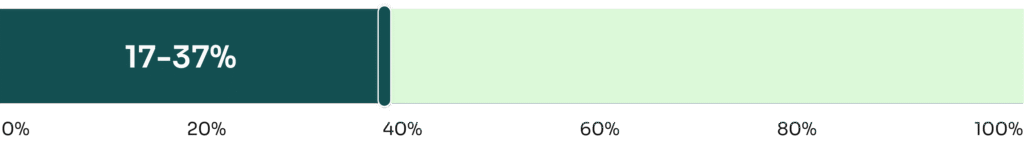

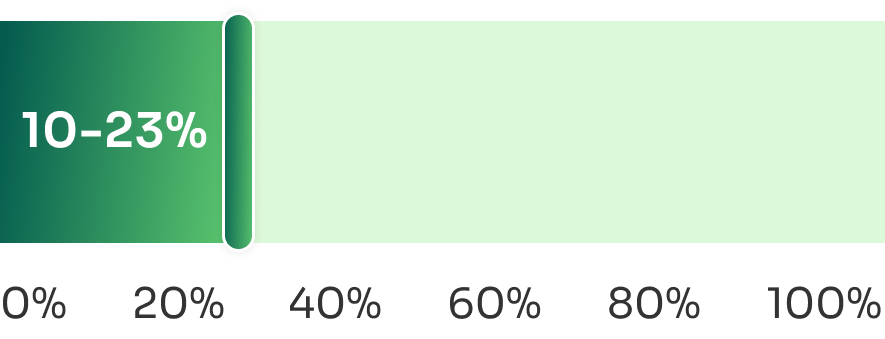

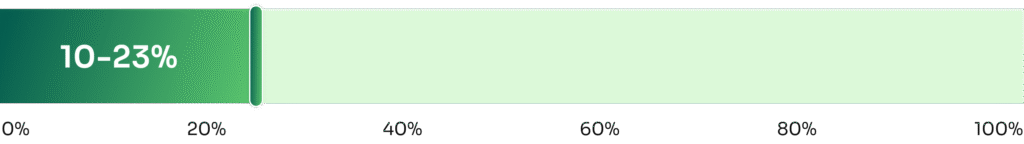

Real data from precision engineering facilities in Singapore show that compressors with Variable Speed Drive (VSD) technology consume between 15% to 45% less energy

Fixed-Speed Compressors

Fixed-Speed Compressors

- Constant speed operation regardless of demand

- Significant energy waste during low-demand periods

- Higher operational costs and carbon footprint

Variable-Speed Compressors

Variable-Speed Compressors

- Adjusts speed based on real-time air demand

- Minimizes energy waste through intelligent control

- Up to 45% reduction in energy costs

*Click chart for more details

Sample Comparison of Energy Usage Patterns

24-hour energy usage data of 50HP (37kW) old fixed-speed and new variable-speed compressor, showing 36% energy savings

Old Fixed-Speed Compressor

New Variable-Speed Compressor

Fixed-Speed Total

4,985 kW

Energy over 24 hours

Variable-Speed Total

3,184 kW

Energy over 24 hours

Energy Saved

36%

(1,801 kW)

Energy over 24 hours

Old Fixed-Speed Compressors

Fixed-speed compressors maintain high energy consumption even during low-demand periods, resulting in significant waste

New VSD Compressors

VSD compressors automatically adjust motor speed to match actual air demand, dramatically reducing energy consumption during off-peak hours

Sample Return on Investment

Clear financial benefits with rapid payback periods - even faster with EEG grant support

Old Fixed-Speed Compressors

New VSD Compressors

Est. annual electricity cost of old Fixed-Speed Compressors based on power meter data

Est. annual electricity cost of new Variable-Speed Compressors based on power meter data

Standard Investment

Project Cost

$49.200

Annual Savings

$29.831

Payback Period

1.6

Years

To full ROI

With Energy Efficient Grant (EEG)

Project Cost

$14.760

Annual Savings

$29.831

Payback Period

0.5

Years

Just 6 months to full ROI

Address

39 Kaki Bukit Road 2, K.B. Warehouse Complex, Singapore 417857

Back To Top